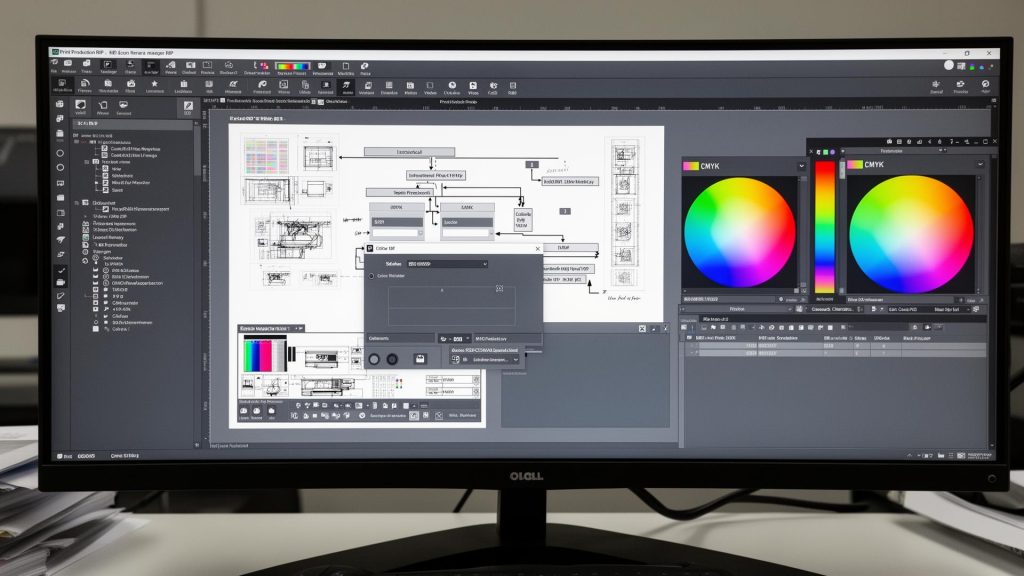

StudioRip

Print-Ready Output in Minutes, Not Hours

How It Works

From file upload to production-ready output in three simple steps

Step 1 –Upload Files

Import your design files — PDF, TIFF, or native formats

Step 2 –Auto-Check & Optimize

StudioRIP runs preflight, screening, and color management

Step 3 –Output & Produce

Send production-ready files to your printer or CTP device

Stop wasting time on packaging rework

Without Impact CAD

- ✕ Manual preflight checks causing production delays

- ✕ Inconsistent color output across different jobs

- ✕ Complex RIP setups that require specialized training

- ✕ Wasted materials from screening and trapping errors

StudioRIP

- ✓ Automated preflight catches errors before production

- ✓ Advanced color management ensures consistent output

- ✓ Intuitive interface — production-ready in hours, not weeks

- ✓ Smart screening and collision detection eliminate waste

See Your Output Before You Print

Why Print Professionals Choose StudioRIP

40% Faster Processing

Automated workflows cut job processing time dramatically

Perfect Color Every Time

Enhance design and production management with real-time tracking and precise estimations.

Zero Production Errors

Automatic preflight, collision detection, and waste calculation

Quick Setup

Works on Windows & Mac — get your team running in hours

30% Material Savings

Smart nesting and waste reduction tools cut material costs

Trusted by Packaging Teams

See how packaging teams are accelerating their workflow

Common Questions

Do you offer financing options?

Yes, we offer flexible financing plans. Contact our sales team to discuss options tailored to your budget.

What warranty is included? .

All machines include a 1-year standard warranty, with 2-year extended warranty available on Production packages

What materials can TOP CNC systems cut?

Our systems cut cardboard, PVC, leather, textiles, plastic, foam, and more—making them versatile for packaging, signage, and manufacturing.

How long does installation take?

Standard installation takes 1-2 days. Our team handles setup, calibration, and initial training to get you running quickly.

Ready to Transform Your Print & Packaging Operations?

Contact Us

We would love to speak with you.

Feel free to reach out using the below details.